Hello hello!

When Jaxx Pacific announced their Max Force series, I went crazy over the Shadowhawk... until I found out that it was not only a spitwad blaster, but it had no trigger.

However... the blaster itself appealed to me so much that I decided I'd get one just to convert it to fire darts and have a proper working trigger, much like how I converted the Xploderz Xranger.

_________________________________________________________________

*****DISCLAIMER*****

Please read through the entire write-up first before attempting your own version.

I wish to warn all of you that the way I did it is really messy on the inside because

I went through alot of trial and error to get the result I was going for.

After reading through the whole write-up, I'm sure that you'll understand what I

went through and I know for sure that you guys will end up with a better,

cleaner, more efficient version of this. Thanks.

_________________________________________________________________

Right! Let's get straight to it.

Things you need: (things I used)

- Dremel with Sanding Drum & Cutting Bit

- Random spare trigger piece

- L-bracket

- Hotglue gun (with hotglue please)

- Bunch of springs (small sized)

- Screws (varying sizes depending on what L bracket you use)

- spare piece of plastic (I used the handle of an old paintbrush)

Before I show you the pictures I want to make it clear that I did not plan to make a "step by step" sort of write-up.

Okay.

So open up your blaster and you should see this:

a closer look:

I know it's not shown in this write-up but I actually chopped the output down, and gooped on a new barrel and made it an internal in-line clip.

Check the vid at the end of the write-up where I talk a lot and give you a firing demo.

Right.

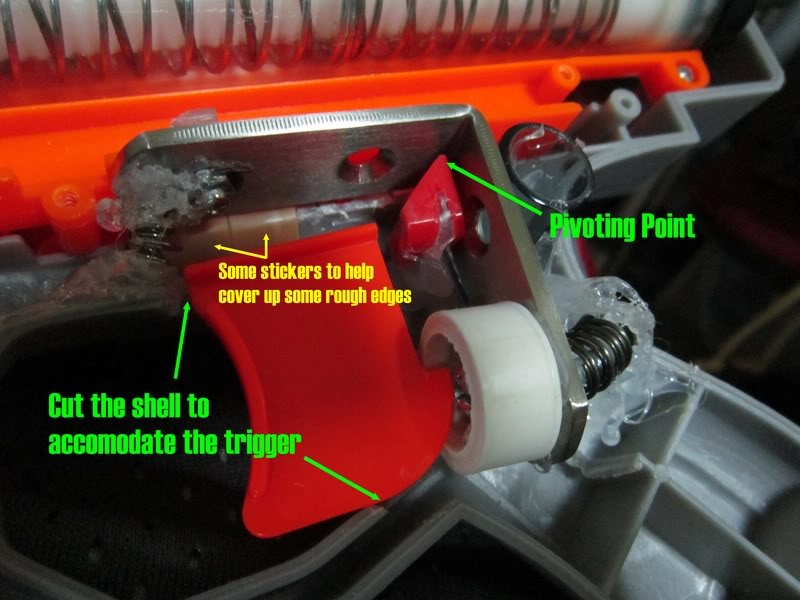

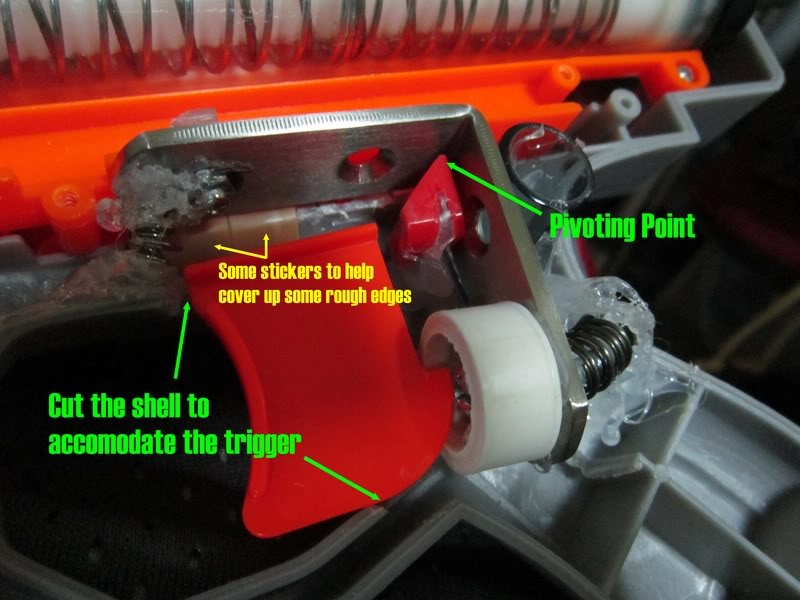

So at the area where I say "Make a cut here", I know it's kinda vague right now but take a look at the next pic and you'll understand.

Basically the cut area is to accomodate the new "tooth" notch that's glued and screwed down into the L-bracket.

That notch is fashioned out of the scrap plastic I mentioned in the "parts list". I got that plastic piece from the body of an old paintbrush.

I have no idea what material it is... maybe Polycarb?

It's definitely NOT acrylic though.

This will be part of the catch mech of the trigger setup.

The rest is actually kinda easy to understand while looking at the picture.

Why do I have 2 areas of hotglued springs?

Because the one on the back provides stability for the L-bracket and the one just below the tooth notch acts as the "catch spring".

Oh yes, I know I didn't mention it in the picture (but I guess this would come with common sense...),

but dremel out the grip area of the shell so that you can fit the L-bracket in, with enough space for a little movement.

another pic:

Sorry, I forgot what trigger I was using. It might have been a Buzz Bee Ultimate Snipe Blast trigger.

I know I cut it into the shape you see above.

The trigger has nothing holding it down. It won't slip out because the slot I cut is almost exactly in the size of the trigger and it rests nicely against the 1/2" pvc stub.

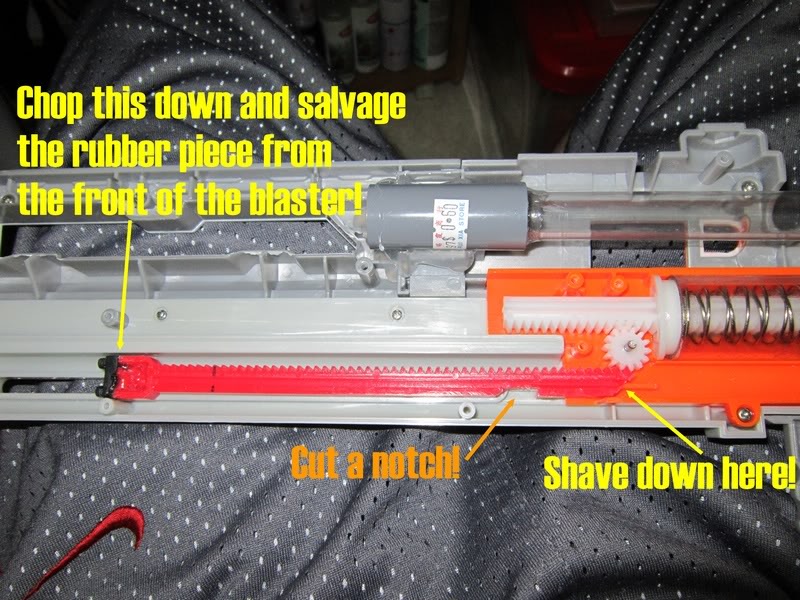

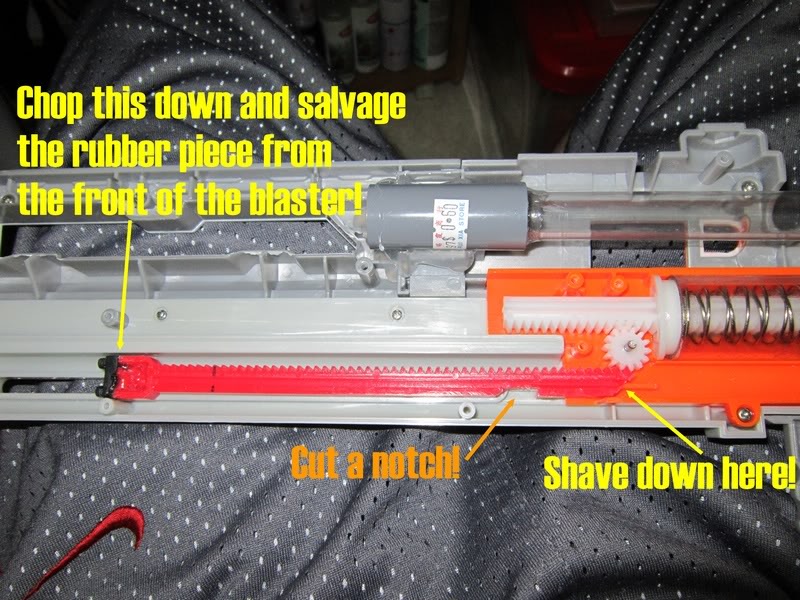

We're almost done:

Measure the correct place where you have to cut your notch for the tooth to go in.

Cut a notch, and also shape the end of the priming rod so that it will travel over the tooth.

Why did I chop the front?

SHOTGUN PUMP FTW!!!!!!!!!

This is so that you can have the grip return to the "forward" position instead of having it to sit at the back end of the priming stroke.

Why did I salvage the rubber piece from the front of the blaster and stick it at the head of the priming rod?

Because the head of the priming rod will smash into the back screwport of the priming grip.

Logic, my friend. Logic.

Now once you're done, it should look something like this:

Now... before you make this fire darts, remember to upgrade the spring.

Inbetween taking these pictures and filming the vid,

I slipped a slightly smaller O-ring infront of the stock O-ring and now it's getting a 100% seal.

Also, I've added a return spring to the pump so it works just like how a PAS does.

For a firing demo (yes, with darts, not spitwads) and everything else (like seal demo, etc),

check my vid (2 parts... LONG but in-depth vid.).

Part 1:

Part 2:

When Jaxx Pacific announced their Max Force series, I went crazy over the Shadowhawk... until I found out that it was not only a spitwad blaster, but it had no trigger.

However... the blaster itself appealed to me so much that I decided I'd get one just to convert it to fire darts and have a proper working trigger, much like how I converted the Xploderz Xranger.

_________________________________________________________________

*****DISCLAIMER*****

Please read through the entire write-up first before attempting your own version.

I wish to warn all of you that the way I did it is really messy on the inside because

I went through alot of trial and error to get the result I was going for.

After reading through the whole write-up, I'm sure that you'll understand what I

went through and I know for sure that you guys will end up with a better,

cleaner, more efficient version of this. Thanks.

_________________________________________________________________

Right! Let's get straight to it.

Things you need: (things I used)

- Dremel with Sanding Drum & Cutting Bit

- Random spare trigger piece

- L-bracket

- Hotglue gun (with hotglue please)

- Bunch of springs (small sized)

- Screws (varying sizes depending on what L bracket you use)

- spare piece of plastic (I used the handle of an old paintbrush)

Before I show you the pictures I want to make it clear that I did not plan to make a "step by step" sort of write-up.

Okay.

So open up your blaster and you should see this:

a closer look:

I know it's not shown in this write-up but I actually chopped the output down, and gooped on a new barrel and made it an internal in-line clip.

Check the vid at the end of the write-up where I talk a lot and give you a firing demo.

Right.

So at the area where I say "Make a cut here", I know it's kinda vague right now but take a look at the next pic and you'll understand.

Basically the cut area is to accomodate the new "tooth" notch that's glued and screwed down into the L-bracket.

That notch is fashioned out of the scrap plastic I mentioned in the "parts list". I got that plastic piece from the body of an old paintbrush.

I have no idea what material it is... maybe Polycarb?

It's definitely NOT acrylic though.

This will be part of the catch mech of the trigger setup.

The rest is actually kinda easy to understand while looking at the picture.

Why do I have 2 areas of hotglued springs?

Because the one on the back provides stability for the L-bracket and the one just below the tooth notch acts as the "catch spring".

Oh yes, I know I didn't mention it in the picture (but I guess this would come with common sense...),

but dremel out the grip area of the shell so that you can fit the L-bracket in, with enough space for a little movement.

another pic:

Sorry, I forgot what trigger I was using. It might have been a Buzz Bee Ultimate Snipe Blast trigger.

I know I cut it into the shape you see above.

The trigger has nothing holding it down. It won't slip out because the slot I cut is almost exactly in the size of the trigger and it rests nicely against the 1/2" pvc stub.

We're almost done:

Measure the correct place where you have to cut your notch for the tooth to go in.

Cut a notch, and also shape the end of the priming rod so that it will travel over the tooth.

Why did I chop the front?

SHOTGUN PUMP FTW!!!!!!!!!

This is so that you can have the grip return to the "forward" position instead of having it to sit at the back end of the priming stroke.

Why did I salvage the rubber piece from the front of the blaster and stick it at the head of the priming rod?

Because the head of the priming rod will smash into the back screwport of the priming grip.

Logic, my friend. Logic.

Now once you're done, it should look something like this:

Now... before you make this fire darts, remember to upgrade the spring.

Inbetween taking these pictures and filming the vid,

I slipped a slightly smaller O-ring infront of the stock O-ring and now it's getting a 100% seal.

Also, I've added a return spring to the pump so it works just like how a PAS does.

For a firing demo (yes, with darts, not spitwads) and everything else (like seal demo, etc),

check my vid (2 parts... LONG but in-depth vid.).

Part 1:

Part 2: