Materials:

- 0.5mm Aluminium Sheet (can be bought from hobby stores or bunnings)

- 3 Day Super Strength Epoxy Resin ($10 at bunnings or k-mart)

- Boltsled (from your longshot...)

- Pliers (needle nose and the fatter kind o.O)

- Perma Marker

- Scissors (to cut out the sheet)

- Some hand-eye coordination...

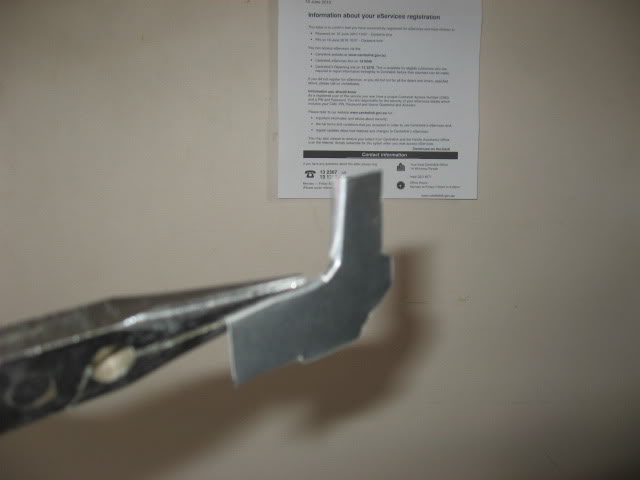

Picture below for people who love pictures.

Step 1:

Place your aluminium sheets and trace it around your sled with a perma marker. Make SURE you cut OUTSIDE the perma marker, not inside it, You will understand why later on.

Step 2:

Sand down lightly the area of reinforcement on L joint of sled and aluminium cut out (to get best bond with glue)

Step 3:

Shape your aluminum with the pliers to make it fit nicely on the sled joint.

Step 4:

Wash plastic under warm water do get rid of the dusty sanded plastic which may get in the way with the bonding. Don't do it with aluminium, it will rust. Pat it down to dry it down with some paper towel

Step 5:

Mix 3 day epoxy together and put it on both the plastic and aluminium sandwiching them together.

You're done! It's a basic write-up but just there to give you guys an idea of what you NEED to do before you add anything better than an LS spring. Keep in mind a LS + NF combo started to wear away at the sled. So like some dude said on these forums... add anything more than the lognshot spring... REINFORCE IT!

I have tested it, it does work in the Longshot, but there is a very thin margin of error if you don't do it properly it won't run smoothly on the guide rails.

Last edited by littlebro05 on Mon Sep 13, 2010 2:18 pm; edited 2 times in total