Seeing as I've got another 5 of these on order, I thought it would be best to single the PAS, to show people the possibilities of this unit.

Tools:

- Basic tool kit

- Hot glue gun

- Dremel/rotary tool with cutting and sanding attachment

Materials:

- 19/32" brass (5cm)

- 1/2" brass (3cm)

- 25mm conduit

- 20mm conduit

- PETG

- spring

As always, start by opening up your blaster. There are 2 screws located underneath the pump grip. Here's a look at the internals:

Cut off the ball launcher, on the last rib, like this:

I've used a piece of 25mm conduit, due to availability. You could use a coupler if you desire. Insert the brown funnel in to the orange housing, and glue in the 25mm conduit with hot glue, like so:

Get your piece of 19/32" brass, and wrap it in e-tape until it fits snugly in the 25mm conduit. Also, wrap the piece of 1/2" brass in e-tape, so it fits snugly inside the 19/32" brass. You could also nest it in 9/16" first, and epoxy all 3 pieces of brass together, and epoxy in to the conduit. But, it's not difficult for it all to be done with e-tape, and just the 2 pieces of brass.

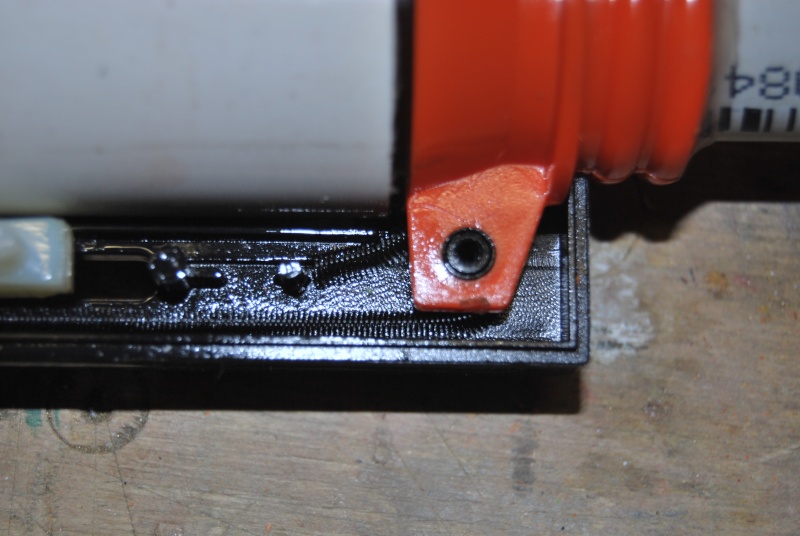

Stick the brass in from the funnel end, and fill the deadspace up with hot glue:

What we're building here, is a stopper for the dart. This blaster vacuum loads, and without this stopper, your darts will be sucked all the way in to the pluger tube. End result, squashed darts, and no firing. This is what it should look like from the barrel end:

Okay, that's it for the coupler. For the barrel, I've used a 30cm length of 20mm conduit, with 30cm Petg nested inside of that with e-tape. A couple of wraps of e-tape on the 20mm conduit, and it's a very snug fit inside the 25mm conduit.

Next is the plunger tube. Remove the plunger rod, head and spring. The stock spring is quite beefy, but I decided to add a spacer for a little more compression. Stock set-up:

There's different ways of doing this. I've used a small piece of 1" pvc, and the cap off of a 10L bottle of water. Cut out the groove for the plunger rod, and glue the spacer on to the stock spring locator:

Stock plunger seal is quite good, so I left it alone. I did add the spring from a Longstrike. It isn't long enough to add momentum through the entire travel of the plunger rod, but it will add power for at least 75% of the travel. Completed assembly:

Now, lubricate the o-rings and re-assemble the plunger tube:

The last part, is to re-locate the return spring of the grip, before re-assembling the blaster. This puts a fair bit more load on the spring, making the priming action feel alot better:

Install the plunger tube, ensuring that the groove on the plunger rod lines up with the track. Re-assemble the blaster, and check that it functions correctly.

All in all, it's a fairly simple and quick blaster to mod, requiring minimal materials. Now for some cosmetics:

Pistol grip:

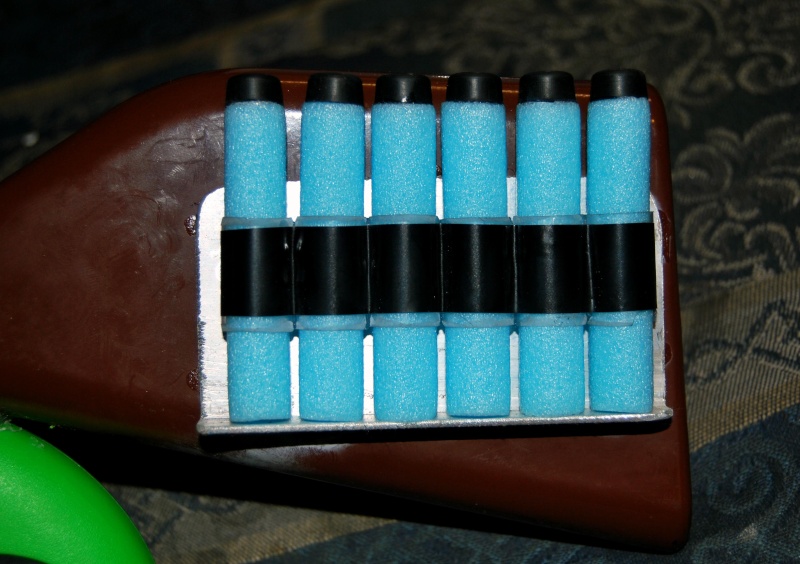

Buttstock ammo holder:

Finished Product:

I've still got some final sanding to finish, then a paint job, and mabye an iron sight on the barrel or something. I'll post pictures when I finally get around to finishing this off.

Ranges:

Stock, flat - 10 feet, maybe...

Modded, flat - 114 feet

Now, I haven't had time to experiment with more spring compression, different barrel material/length, dart weight etc. but I'm fairly impressed with the results so far. I feel it's as accurate, if not better, than my LShot.

I've tested the range with heavy sili's, tails cut down to 5mm, and double-washered stingers. Lighter darts fish-tail like crazy.

Before you go crazy with springs, the plunger rod does not look overly strong in my opinion, so reinforcement/replacement would be advisable.

And, for those who don't know already, check out my sales thread to purchase one of these blaster's.

Cheers,

Last edited by clunk07 on Sun May 29, 2011 4:26 pm; edited 1 time in total